Table of Contents

- Introduction

- Applications of Steel Pipes in Infrastructure

- Advantages of Using Steel Pipes

- Recent Developments in Steel Pipe Manufacturing

- Challenges and Considerations

- Conclusion

Introduction

Across the modern built environment, steel pipes are essential elements that deliver enduring value in a variety of applications. Their widespread adoption speaks directly to their reputation for reliability and strength. From water distribution to vital energy systems, steel piping underpins both the physical integrity and operational reliability of infrastructure. In growing urban centers and industrial hubs, such as steel pipe Tulsa, have become central to meeting the complex demands of new construction and ongoing infrastructure maintenance. This is particularly important in regions where the pressures of population growth and industrial expansion put extra strain on existing systems. The adaptability of steel piping plays a crucial role in upgrading aging infrastructure and accommodating the increased water, energy, and transport needs of expanding communities. This versatility keeps communities resilient and ensures that systems function smoothly in both routine operations and extreme conditions, such as natural disasters or sudden spikes in usage.

What truly sets steel pipes apart is their remarkable combination of strength, adaptability, and cost efficiency over the long term. Their critical role extends from the foundational frameworks in skyscrapers, where they are often engineered to precise specifications, to the sprawling underground networks that carry water, oil, and gas across vast distances. In many cases, steel pipes act as a safeguard, preventing leaks and contamination that could jeopardize public health and environmental safety. As public and private sectors continue to invest in robust infrastructure, leveraging the unique benefits of steel piping systems becomes increasingly important for future-proofing the world’s most vital assets. Governments and private enterprises alike recognize that well-chosen piping can significantly reduce maintenance costs and extend the lifespan of critical facilities, ultimately leading to fewer service interruptions and stronger economic growth.

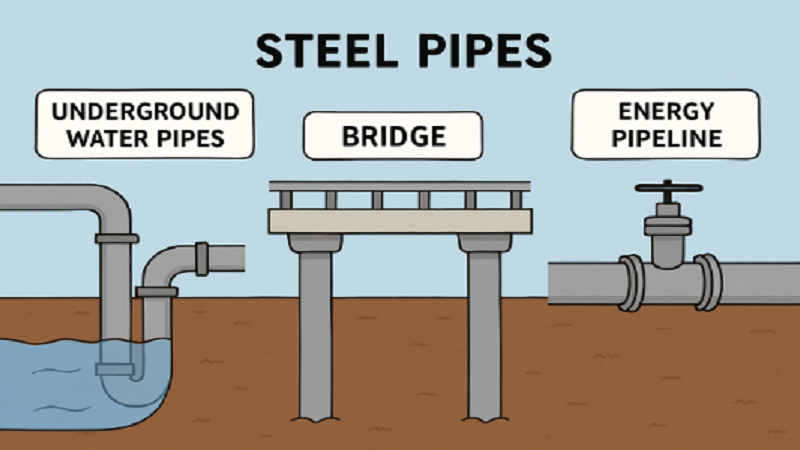

Applications of Steel Pipes in Infrastructure

- Water Supply and Wastewater Management: With high resistance to corrosion and mechanical damage, steel pipes serve as reliable conduits in municipal water supply and drainage systems. These pipes help safeguard water quality, ensuring that residential and commercial buildings receive a steady, uncontaminated flow. For regions prone to extreme weather events or seismic activity, steel pipes offer additional peace of mind, as they resist breakage and maintain supply even under challenging circumstances. Modern coatings enhance their resistance to common waterborne chemicals, extending their usable life in harsh conditions and minimizing the risk of pipe failures that can cause expensive and disruptive water main breaks.

- Structural Support: Serving as the backbone for countless projects, steel tubes and pipes provide vital support in bridges, roadways, and building frameworks. Their ability to bear tremendous weight allows designers to build higher and span greater distances, helping urban planners and engineers create more ambitious and durable infrastructure. The flexibility of design offered by steel pipes allows them to be used in complex architectural forms, supporting both aesthetic and functional goals. Over time, advancements in welding, fabrication, and design software have further expanded the range of infrastructure projects that benefit from steel’s inherent strength.

- Energy Sector Infrastructure: The energy industry relies heavily on steel piping for transporting natural gas, crude oil, and chemicals, as well as for supporting renewable power facilities, including hydroelectric, solar, and wind installations. These pipes undergo rigorous testing to withstand extreme pressures and temperatures, making them essential for the safe, long-distance transmission of energy products. The ability to safely transport volatile substances over vast distances without leakage or rupture is a key factor driving continued investment in steel pipelines worldwide. With the increasing complexity of modern energy networks, the materials chosen must be dependable, and steel consistently meets or exceeds regulatory requirements.

Advantages of Using Steel Pipes

- Durability and Strength: Steel pipes are highly regarded for their ability to resist deformation, crack propagation, and physical impacts. This makes them ideal for supporting critical infrastructure loads and for services that operate at high pressures. Over time, this resilience translates into fewer failures and reduced downtime for essential infrastructure systems. Their strength-to-weight ratio is particularly attractive for engineers working on projects in areas with challenging soil conditions or those requiring seismic resistance.

- Corrosion Resistance: Innovations in alloy composition and protective coatings have significantly boosted the ability of steel pipes to resist corrosion from water, chemicals, and environmental exposure, minimizing long-term maintenance costs and disruptions. This is especially valuable in coastal regions, industrial zones, or areas with aggressive soils where other piping materials might deteriorate quickly. As noted by ScienceDirect, corrosion resistance plays a crucial role in ensuring durability and reliability. Technological advancements continue to yield even more robust solutions, which are tailored to fit local environmental conditions and the specific needs of each project.

- Versatility: The ability to fabricate steel pipes in virtually any diameter or thickness ensures they can be tailored to virtually any infrastructure need, from compact residential systems to massive industrial networks. Advanced computer-aided design (CAD) and manufacturing processes enable providers to produce custom shapes and configurations rapidly, minimizing lead times and ensuring a close match with project requirements. This flexibility also encourages innovation, as engineers and architects can experiment with ambitious designs knowing that steel piping offers the adaptability needed to bring their visions to life.

Recent Developments in Steel Pipe Manufacturing

Modern steel manufacturing is advancing rapidly to meet new demands for efficiency and sustainability. Today’s production facilities incorporate recycled steel and low-carbon alloys, thereby reducing their environmental footprint without compromising pipe quality. Efforts to produce greener steel are supported by international climate initiatives, which drive manufacturers to continually refine their smelting and forming processes. Automation and modular production methods have significantly improved product consistency and expedited the construction schedule for large projects, thereby reducing waste and cost overruns. These innovations position steel pipes as forward-thinking infrastructure solutions that balance performance with responsibility, a critical factor as municipalities face increasing pressure to meet climate goals while maintaining reliable service to their populations.

Additionally, advanced pipe inspection and non-destructive testing technologies enable operators to proactively monitor system health, reducing the risk of unexpected failures and costly emergency repairs. Machine vision and ultrasound-based inspection systems can detect microcracks or internal flaws before they escalate into major problems, providing peace of mind for both public and private sector stakeholders. These inspection advancements not only protect investments but also contribute to improved safety for workers and the public.

Challenges and Considerations

Despite their numerous advantages, the steel pipe industry is not without challenges. Raw material price fluctuations can impact project budgeting and timelines, while a shortage of skilled labor can slow both manufacturing and onsite installation processes, sometimes introducing delays that affect entire communities or industrial operations. Additionally, logistics for transporting and installing large steel pipes often require specialized equipment and meticulous planning.

Compliance with stringent environmental and safety standards demands regular technological upgrades, encouraging manufacturers to remain agile and innovative in their approaches. Continuous investment in employee training, quality control processes, and compliance systems is necessary to prevent costly errors and regulatory penalties. Construction managers must also weigh the initial investment against long-term operational savings offered by steel systems, factoring in ongoing maintenance and the potential for future upgrades as regulations and needs evolve. Decision-makers must balance these concerns with the compelling long-term benefits that steel offers in terms of reliability and lifecycle cost savings.

Conclusion

As infrastructure demands rise worldwide, steel pipes remain indispensable for delivering lasting performance in the most critical systems. Their unmatched combination of strength, durability, and adaptability makes them the material of choice for projects that demand uncompromising dependability. By integrating new manufacturing techniques and adhering to stricter standards, the steel pipe industry continues to evolve, meeting both today’s and tomorrow’s infrastructure challenges. Ultimately, steel piping is not just a product, but a strategic asset that empowers communities and industries to flourish for generations to come.