Key Takeaways

- Durable rigging depends on strong materials, smart engineering, and protection against environmental stress.

- Regular inspections, maintenance, and proper training significantly extend equipment lifespan.

- Innovations like smart sensors and advanced composites are shaping the future of long-lasting rigging gear.

- Investing in durability reduces downtime, improves safety, and saves long-term costs.

Principles of Long-Lasting Rigging Equipment

Rigging equipment is the backbone for safe and efficient lifting and hoisting across construction, mining, shipping, and energy industries. From wire rope slings and chain hoists to shackles and synthetic web slings, the performance and reliability of these components directly influence workplace productivity and safety. The operational lifespan of rigging equipment hinges on factors like load capacity, resistance to abrasion, environmental adaptability, and the inherent quality of materials and engineering.

Businesses in growth areas such as rigging Little Rock rely on equipment designed for extended service, reducing costly downtime and repair cycles. By understanding the traits that contribute to durability—such as fatigue resistance, robust construction, and user-friendly maintenance—organizations can achieve both safety compliance and cost efficiency.

Choosing Materials for Durability

Material selection is foundational to designing rigging components that stand the test of time. Steel remains the industry standard for its unmatched strength and fatigue resistance. Still, advancements have brought synthetics like high-performance polyester and aramid fibers to the forefront, offering lightweight alternatives that excel in environments sensitive to weight or moisture. Composite materials, blending metals with advanced polymers, further enhance corrosion resistance and flexibility.

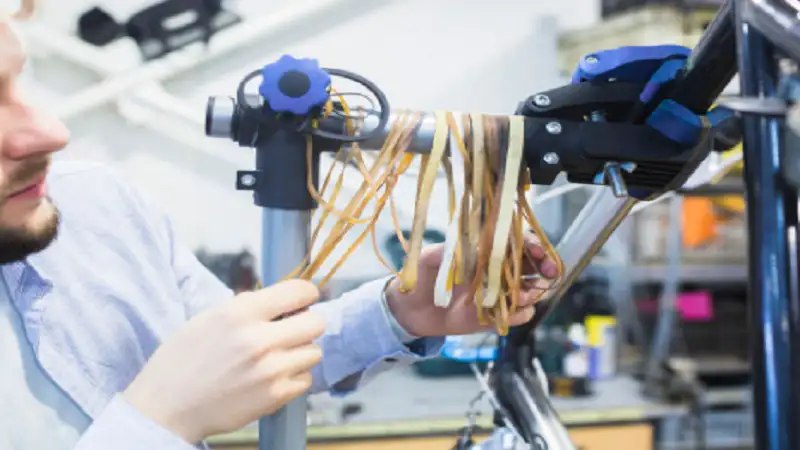

The Role of Engineering and Design Innovations

Technological advancements are redefining rigging design and manufacturing. Computer-aided design (CAD) tools and simulation software allow engineers to optimize geometry, reduce stress concentrations, and enhance fatigue life. Advanced coatings and surface treatments, such as galvanizing or epoxy sealing, provide additional layers of protection against corrosion and abrasion.

Engineering breakthroughs like load-indicating hardware, self-locking hooks, and modular rigging components improve operational efficiency and extend service intervals by reducing routine wear and enhancing safety features. Collectively, these innovations contribute to safer, longer-lasting rigging gear.

Environmental and Operational Stress Factors

Rigging equipment frequently operates in environments that expose it to corrosion, extreme moisture, temperature fluctuations, and ultraviolet (UV) radiation. These conditions can degrade standard metals and fabrics, leading to premature failure if not adequately anticipated during design. Robust design integrates protective finishes, UV inhibitors, and drainage features to prevent moisture buildup and withstand the rigors of continual use.

Key Maintenance Strategies to Extend Rigging Life

Routine inspection and maintenance are critical for maximizing equipment lifespan and sustaining safety standards. Scheduled load testing, thorough visual inspections for wear and deformation, proper lubrication, and correct storage away from chemicals and sunlight all contribute to preserving equipment integrity.

Training and Human Factors in Rigging Durability

The human element cannot be underestimated when extending the functional life of rigging equipment. Well-trained operators are less likely to overload components, misuse hardware, or neglect necessary inspections. Customized training programs focus on proper procedures for equipment choice, rigging configuration, and recognition of early signs of wear or damage.

Common errors, such as exceeding rated capacities or using the wrong sling type for hazardous loads, can be minimized when workers have thorough, up-to-date knowledge. Regularly refreshed training sessions correlate to fewer incidents, reduced repair costs, and maximized equipment longevity.

Adapting to New Industry Demands

Increasingly complex construction and industrial projects require rigging systems tailored for unique challenges such as confined spaces, extreme weather, or unusual load geometries. Custom-designed rigging hardware offers the adaptability necessary for specialized tasks while leveraging the most durable materials and design practices suited for each scenario.

Looking Forward: The Future of Durable Rigging Equipment

The next generation of rigging equipment will integrate emerging trends in materials science—such as nanostructured metals and self-healing polymers—that promise superior longevity and reduced environmental impact. Smart sensors are already being adopted to monitor load cycles, detect micro-cracks, and alert operators to approaching fatigue thresholds, allowing for predictive maintenance before failures occur.

Designing for Performance and Safety

Enduring rigging equipment results from intentional design, robust materials, forward-thinking engineering, and a commitment to ongoing maintenance and training. Proactively addressing environmental, operational, and human factors ensures rigging systems perform reliably and safely under the most demanding conditions. Companies that invest in these principles experience fewer accidents, lower maintenance costs, and longer intervals between equipment replacement.